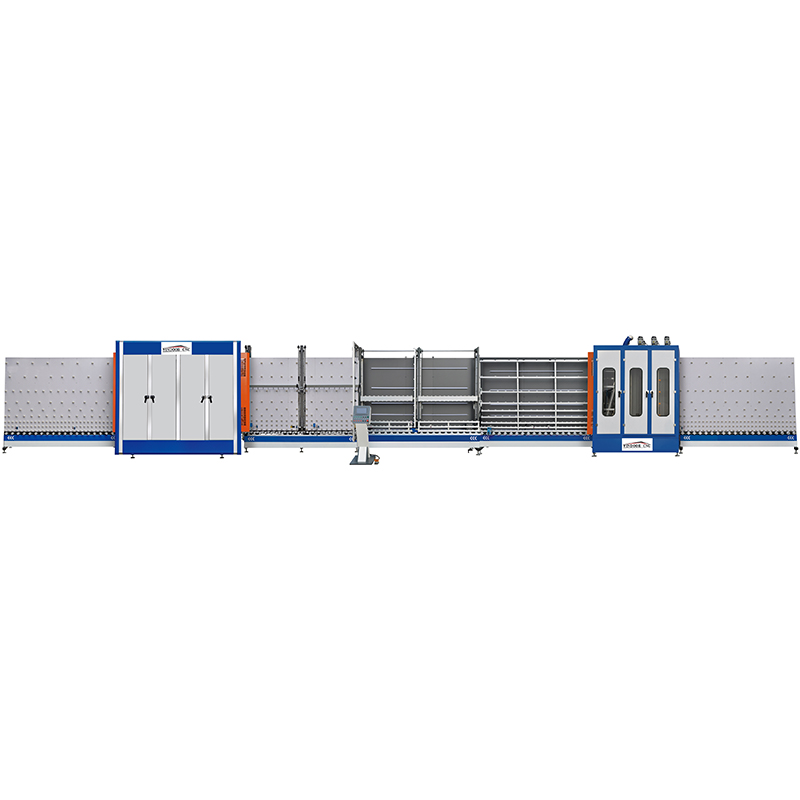

INSULATING GLASS INFLATABLE FLAT-PRESS PRODUCTION LINE WDCQ2500B/2000B

INSULATING GLASS INFLATABLE FLAT-PRESS PRODUCTION LINE WDCQ2500B/2000B

Features

1.PLC control, touch screen man-machine interface, easy to operate, intuitive, manual or automatic control.

2.The production line can automatically identify coated glass and low-E glass, feeding automatic sheet arrangement (independent transmission).

3.Cleaning box double bottom plate structure, the upper part bevel gear connection, stable performance, long life.

4.Reasonable distribution of lamp tube, segmented control, better detection of glass cleanliness.

5.Aluminum bar positioning is accurate, positioning distance adjustment is convenient; Cleaning air knife automatic ally adjusts according to glass thickness.

6.The third and seventh sections can be pre-stored glass, effectively improving the production efficiency.

7.The pressure of the plate is precisely adjusted, and the lead screw is driven to complete the laminating, laminating and inflating in one time, and the laminating is stable.

8.Automatic detection of glass length, height, thickness, automatic adjustment of the best inflation space.

9.Two, three and four layers insulating glass aeration (argon), automatic calculation of aeration, high concentration.

Technical parameters

| MODEL | WDCQ2500B/2000B |

| Power | 380V 50Hz 35KW |

| Air Pressure | 0.6~0.8Mpa |

| Max working Size | 2500×3500mm 2000*2500mm |

| Min working Size | 280×480mm |

| Glass washing thickness | 3~18mm |

| Insulating glass thickness | ≤80mm |

| Transfer Speed | 0~50m/min |

| Washing speed | 2~15m/min |

| Overall dimension | 24800×2700×3550mm |

1. The equipment is made of high-quality steel, with good rigidity, stability and long service life.

2. The equipment runs stably and has low failure rate in the production process.

3. The machine is highly automated, saving labor. efficient.

4.The equipment is easy to operate and learn.